After years of configuring and supplying diesel generator sets for export projects, this is one of the most misunderstood questions I see from buyers and even some engineers. Many people assume that running a generator lightly loaded saves fuel and reduces wear. In real projects, that assumption is usually wrong.

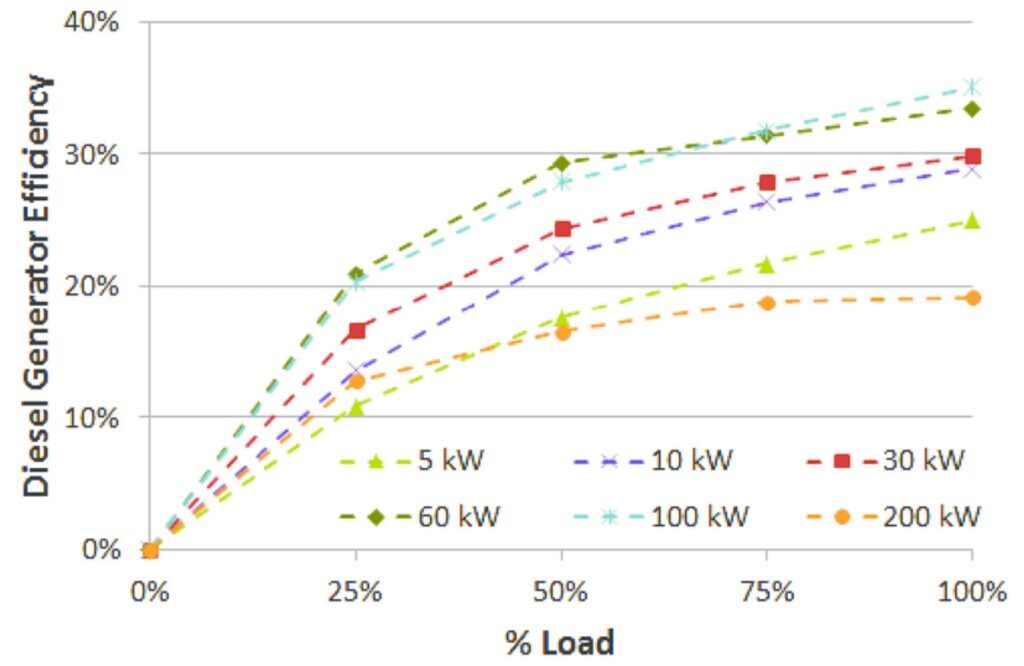

From real operating data and site experience, a diesel generator set is most fuel-efficient when running at roughly 70–80% of its rated load.

Below this range, fuel efficiency drops and long-term engine problems increase. Above it, fuel consumption rises faster than useful output and thermal stress becomes a real concern.

This pattern is consistent across most industrial diesel gensets, regardless of brand.

Why diesel generators are most efficient at 70–80% load

1. Light load operation wastes fuel

When a generator runs below about 40–50% load:

- Combustion temperature is too low

- Fuel does not burn completely

- Specific fuel consumption (SFC) increases

- Issues like wet stacking and carbon buildup start to appear

In practice, I’ve seen standby generators that look “almost unused” after two years, yet internally show early wear because they spent most of their life running at 25–30% load.

2. The efficiency peak comes before full load

Around 70–80% load:

- Combustion is stable

- Turbochargers operate in their optimal range

- Fuel is converted into electrical power most efficiently

- kWh produced per liter of diesel reaches its best point

This is not accidental. It is exactly why manufacturers’ best fuel consumption figures usually sit in this load range.

3. Near-100% load is not an efficiency target

Running at 90–100% load:

- Fuel consumption rises disproportionately

- Cooling margins shrink

- Exhaust and winding temperatures increase

- Long-term reliability declines

In export projects, I always treat 100% load as a short-duration limit, not a normal operating point.

What this means for generator sizing (where many buyers go wrong)

Here is the counter-intuitive reality:

The most efficient generator is rarely the smallest unit that just matches your calculated load.

In real applications, I usually size generators so that:

- Normal operating load sits at 65–80%

- Peak load stays below 85–90%

- Emergency load may briefly reach 100%

A simple example

If a site has a real continuous load of 200 kW, the efficient choice is often:

- A 250–300 kW generator, not a 200 kW unit

Over time, the correctly sized generator will:

- Burn less fuel per kWh

- Run cleaner internally

- Require fewer corrective maintenance interventions

- Deliver a longer service life

When this rule does not fully apply

Based on project experience, there are cases where the 70–80% guideline must be evaluated differently:

- Highly variable loads (cranes, crushers, elevators)

- Very short-runtime standby generators

- Parallel generator systems with controlled load sharing

In these situations, efficiency should be assessed at the system level, not by looking at one generator in isolation.

A practical takeaway worth remembering

Diesel generators are designed to work, not to idle.

Running them lightly loaded for long periods wastes fuel and quietly shortens engine life.

Before choosing a generator size, I always recommend answering three questions:

- What is the real average load, not the theoretical maximum?

- How many hours per year will the generator actually run?

- Will it operate at low load for long, continuous periods?

Those answers matter far more than brochure fuel numbers.