I’ll explain this the same way I usually do in real projects—not theory, not manuals, but what I’ve actually seen go wrong over time.

A diesel generator running at no load isn’t “doing nothing.”

It’s quietly creating problems that usually appear only when the generator is finally needed.

In practice, a diesel generator that runs repeatedly at no load is more likely to fail during an emergency than one that runs briefly under proper load.

This catches many buyers by surprise, especially those who believe “starting it regularly” is enough to keep it healthy.

What “no load” really means in real use

No load means:

- The engine is running

- The alternator is spinning

- Electrical demand is minimal (often under 10–15% of rated capacity)

Common situations where this happens:

- Weekly test runs with breakers open

- Oversized generators installed “just in case”

- Sites where loads were reduced but generators were not re-sized

On paper, nothing looks wrong. In reality, the engine is operating outside its intended range.

What actually happens inside the engine

1. Incomplete combustion starts immediately

Diesel engines are designed to work under heat and pressure.

At no load:

- Cylinder temperatures stay too low

- Fuel does not burn completely

- Carbon residue begins to form

There are usually no alarms, no warning lights, and no obvious noise changes. But the process starts within minutes.

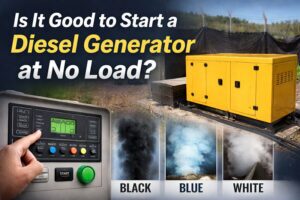

2. Wet stacking – the first visible warning

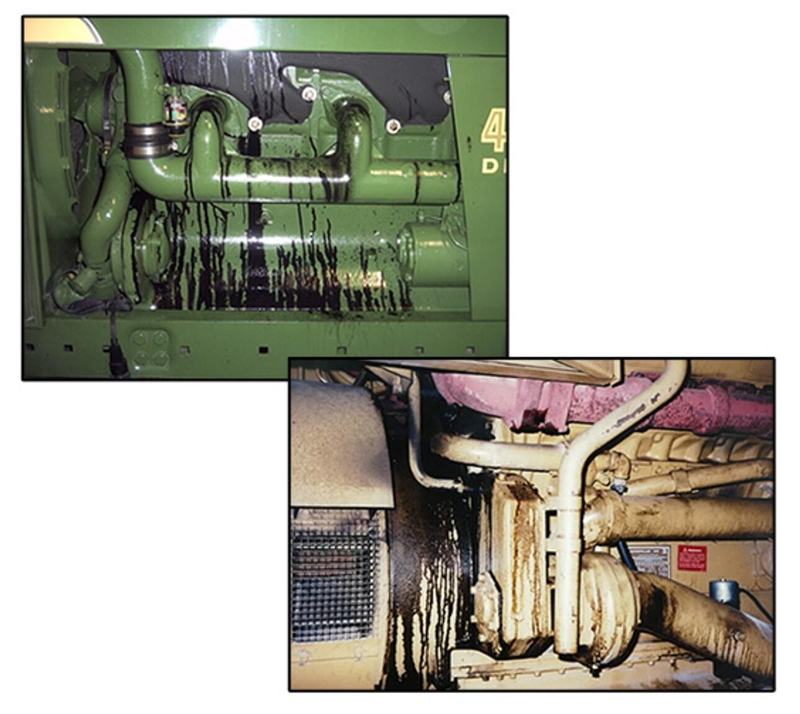

In real export projects, I often receive photos showing:

- Black, oily exhaust

- Soot buildup around the muffler

- Fuel residue at exhaust joints

This is wet stacking.

What it means:

- Unburned fuel is passing into the exhaust

- Carbon is accumulating internally

- Combustion efficiency is poor

Wet stacking is not a manufacturing defect.

It is almost always a usage condition.

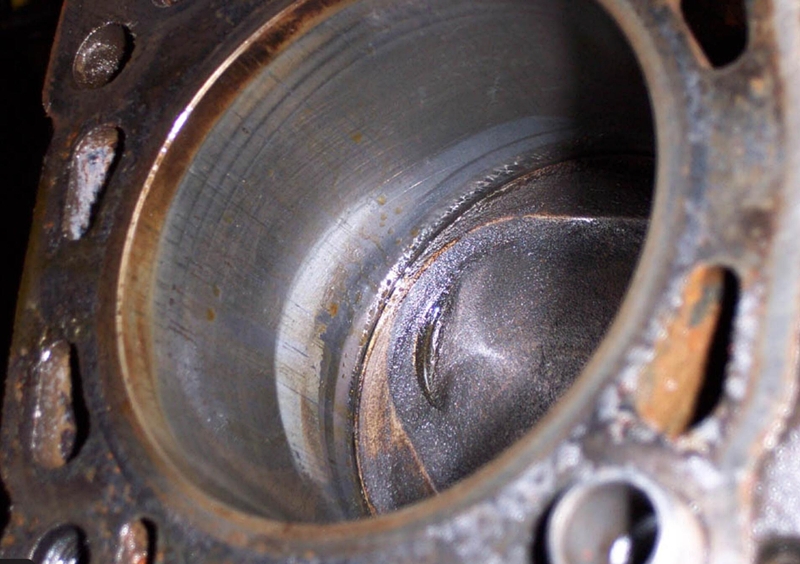

3. Cylinder glazing – the long-term damage

If low-load or no-load operation continues:

- Carbon deposits polish the cylinder liner

- The liner becomes too smooth

- Piston rings can no longer seal properly

Once glazing occurs:

- Oil consumption increases

- Compression drops

- Starting becomes harder

- Output stability declines

At this stage, normal operation alone will not fully reverse the damage.

4. Fuel dilution and oil degradation

Another issue I see more often than people expect:

- Unburned diesel washes down cylinder walls

- Fuel mixes with lubricating oil

- Oil viscosity drops

The generator may still start and run, but internal wear accelerates quietly.

Why the problem is often ignored

This is the most dangerous part.

A no-load generator usually:

- Starts easily

- Runs smoothly

- Shows no alarms

- Passes casual inspection

So users assume:

“If it runs, it must be fine.”

In reality, the damage is cumulative, not immediate. Problems surface months or years later—often during a real outage.

When no-load operation is acceptable

No-load running is not always wrong.

Generally acceptable:

- Very short start-ups

- Maintenance checks

- Initial commissioning steps

High-risk patterns:

- Weekly or monthly test runs with no load

- Long idle runs “just to keep it warm”

- Oversized generators serving small, stable loads

If I know a generator will rarely reach proper load, I usually recommend planning corrective measures early rather than reacting later.

The practical rule I rely on

A diesel generator should regularly operate at no less than 30–40% of its rated load.

Below this range:

- Combustion quality deteriorates

- Carbon accumulation accelerates

- Long-term reliability declines

This principle applies regardless of brand or market.

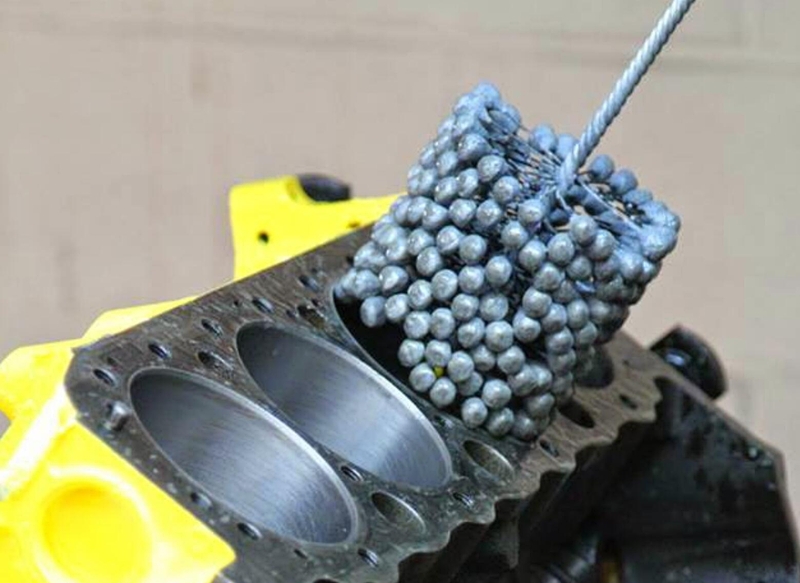

How professionals prevent no-load damage

In real projects, this issue is usually solved in one of three ways:

- Load bank testing

- Provides controlled artificial load

- Burns off carbon deposits

- Verifies real performance

-

Correct generator sizing

- Avoids “bigger is safer” thinking

- Matches output to realistic demand

-

Smarter testing procedures

- Closed-breaker testing

- Rotating or scheduled load application

- Avoiding idle-only routines

When I actively warn customers

If a buyer tells me:

- “We’ll only run it occasionally”

- “Most of the time it won’t have load”

- “We just want to keep it spinning”

That’s when I slow the conversation down.

Because the real risk isn’t today—it’s the day the grid fails and the generator doesn’t perform as expected.

Conclusion

Running a diesel generator at no load:

- Will not cause instant failure

- Will reduce reliability over time

- Often leads to failures at the worst possible moment

A generator is a working machine, not a display unit.

If it doesn’t operate under load, it isn’t truly being maintained.