I’ve been exporting and configuring diesel generator sets for years, and one question keeps coming up — from distributors, project engineers, and even experienced buyers:

“Which diesel generator is the most fuel-efficient?”

I understand why people ask this. Fuel cost is real money, especially for prime power, rental fleets, or sites running generators daily.

But based on real projects — not brochures — my answer is always the same:

There is no such thing as a universally “most fuel-efficient” diesel generator.

Anyone giving a single model or brand as the answer is oversimplifying a problem that is fundamentally conditional.

This article is not about optimizing fuel consumption numbers.

It’s about correcting the way the question is usually asked in the first place.

Fuel efficiency is not a fixed property of a generator

In practice, I see buyers compare generators as if fuel efficiency were a fixed specification — like engine displacement or alternator size.

It isn’t.

Fuel consumption is the result of how a generator is sized, loaded, and operated under real conditions.

The same generator can appear:

- Very fuel-efficient in one project

- Surprisingly inefficient in another

with no hardware changes at all.

What actually determines diesel generator fuel efficiency

1. Actual load ratio matters more than brand or model

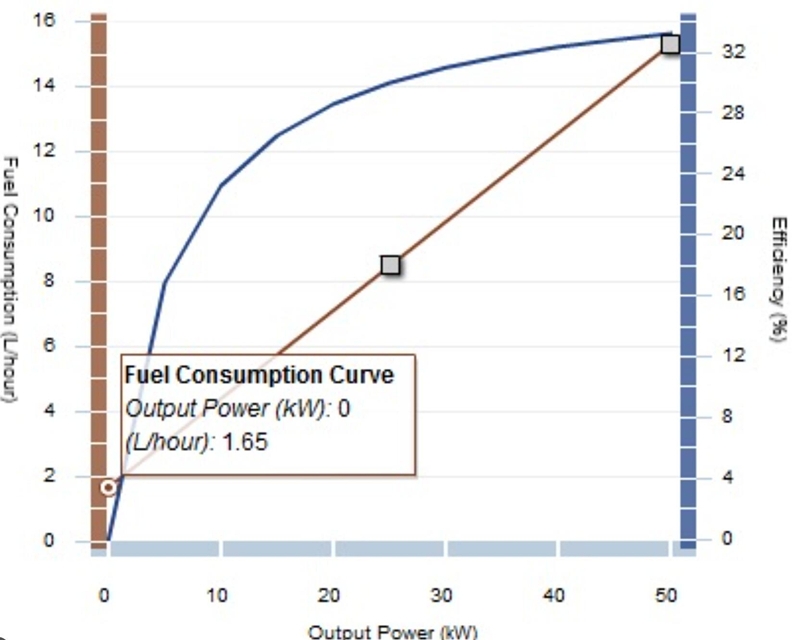

Most diesel engines reach their best fuel efficiency in a mid-to-high load range, not at light load.

In real export projects, I often see:

- A 200 kVA generator supplying 40 kVA

- A 500 kVA generator backing up a site that never exceeds 120 kVA

On paper, the generator looks “safe” and “high quality.”

In operation, it is inefficient by design.

Running an oversized generator is one of the most common reasons for poor fuel efficiency.

2. Duty cycle changes the entire equation

Standby, prime, and continuous operation are not just labels — they change how fuel efficiency should be evaluated.

-

Standby power: short runs, low annual hours

Fuel efficiency is rarely the deciding factor. -

Prime power: long daily operation with variable load

Part-load efficiency becomes critical. -

Continuous base load: steady operation near rated output

Engine sizing and RPM selection dominate fuel performance.

I often see buyers chasing “fuel-efficient models” when the real mistake was choosing the wrong operating category from the start.

3. Real load profiles matter more than brochure fuel charts

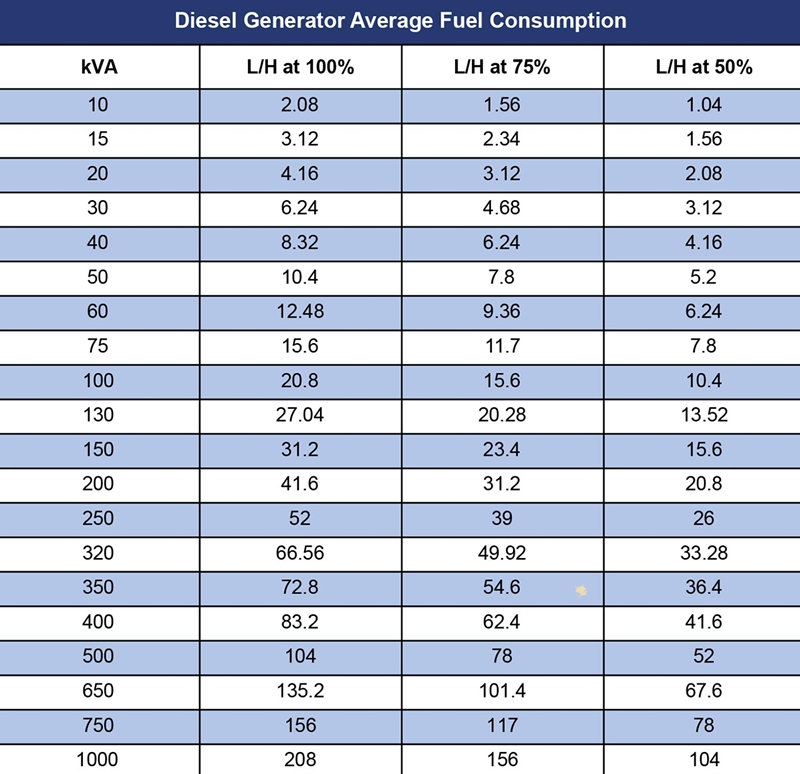

Manufacturers publish fuel consumption at:

- 25%

- 50%

- 75%

- 100% load

These figures are useful — but incomplete.

Real sites involve:

- Motor starting currents

- Load spikes

- Seasonal changes

- Human behavior

Two sites using the same generator model can burn very different amounts of diesel purely because their load behavior over time is different.

4. Oversizing quietly destroys efficiency over time

This is the part many buyers don’t like to hear.

I’ve repeatedly seen generators oversized “for safety,” then operated at light load for years.

The result is not just higher fuel consumption per kWh, but also:

- Carbon buildup

- Wet stacking

- Increased maintenance issues

A slightly smaller generator running at a healthy load is usually more fuel-efficient than a large one idling through its life.

When clients ask me about fuel efficiency, I don’t start with brands, engines, or marketing claims.

I start with this principle:

Fuel efficiency is a matching problem, not a product feature.

Fuel consumption depends on multiple interacting factors such as load ratio, duty cycle, operating environment, and sizing decisions.

For a deeper technical explanation of these diesel generator fuel consumption factors, see our complete guide.

The most fuel-efficient diesel generator is simply one that is:

- Correctly sized

- Matched to the real load profile

- Operated in its efficient load band

Everything else is secondary.

When “fuel-efficient” comparisons actually make sense

To be fair, comparisons can be meaningful — but only under controlled conditions:

- Same engine family

- Same RPM

- Same alternator class

- Same load range

- Same application type

Only then does comparing liters per hour have practical value.

Outside those conditions, fuel consumption numbers often mislead more than they help.

When I don’t recommend chasing fuel efficiency

Based on experience, I don’t prioritize fuel optimization when:

- The generator is purely emergency standby

- Annual runtime is low

- Fuel logistics are simple

- Reliability matters more than marginal savings

In these cases, stability, supportability, and correct configuration matter far more than chasing a theoretical efficiency advantage.

Conclusion

If there’s one sentence I’m comfortable standing behind — even out of context - it’s this:

There is no “most fuel-efficient” diesel generator -only generators that are well or poorly matched to their real operating conditions.

That conclusion holds across brands, countries, engine types, and years of real-world operation - not just specification sheets.