Routine maintenance of an electric generator is crucial for its reliability and long lifespan. But how do you keep your generator in top shape? Let’s break down the steps for you.

Electric generator maintenance is essential for preventing breakdowns and ensuring optimal performance. Following these steps will help maintain your equipment’s reliability and efficiency over time.

Maintaining a generator involves several tasks, from inspecting the engine and cooling system to cleaning and lubricating critical parts. In this article, we'll go through the key steps you need to follow to keep your generator running smoothly.

How to Perform Routine Inspections on Your Generator?

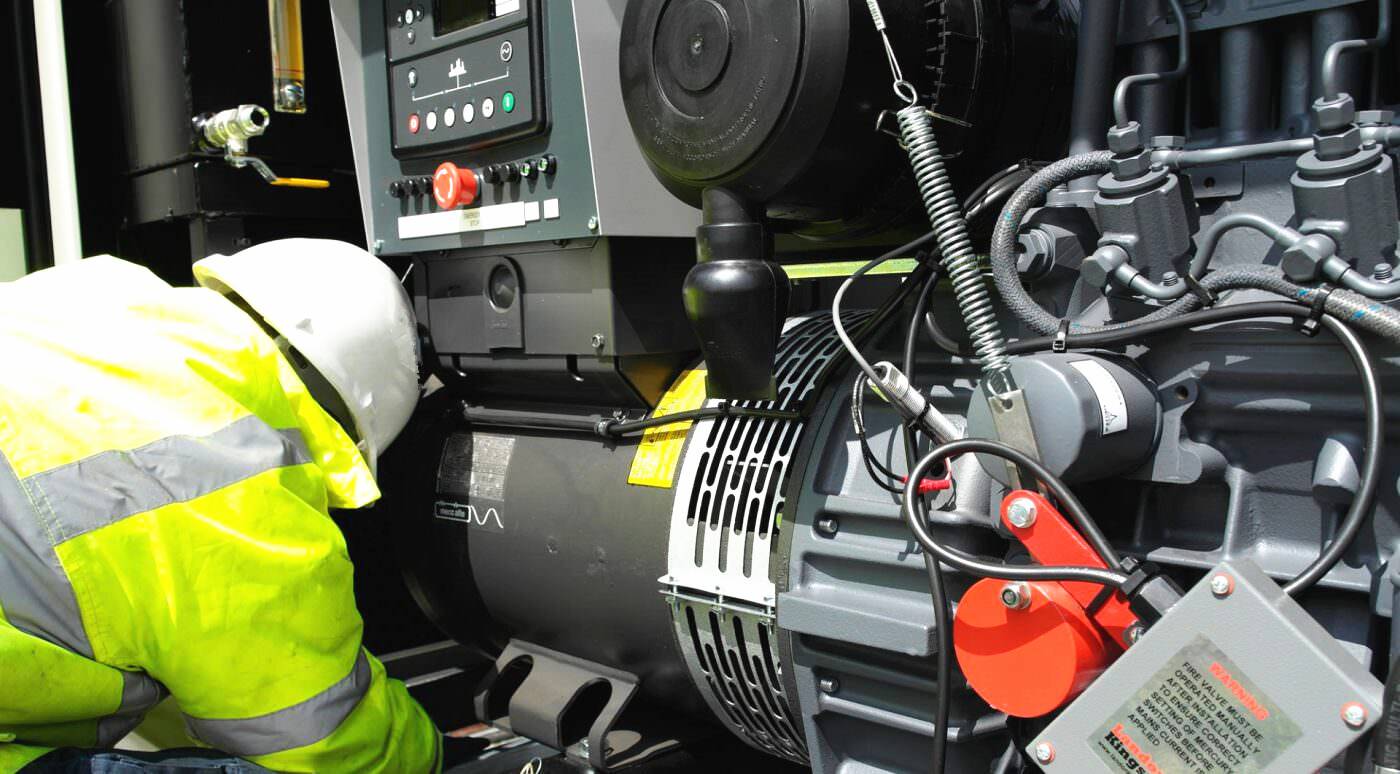

Inspecting your generator regularly can help you identify potential issues before they become serious problems. It's essential to conduct both visual and operational inspections.

Routine inspections are vital for identifying issues early. These checks allow you to catch any wear or damage before they affect the generator's performance.

Engine and Components Inspection

The engine is the heart of your electric generator. Start by checking the oil level and the condition of the oil. If it's low or dirty, change it. Similarly, look at the fuel filter, air filter, and exhaust system. These parts are prone to wear and clogging, so keep them clean and replace them when necessary.

Battery and Electrical Connections

Always inspect the battery terminals for corrosion. Clean them if needed and check the voltage. Ensure that all electrical connections are secure. Loose connections can cause poor performance or complete failure.

Cooling System

The cooling system plays a crucial role in maintaining the generator's temperature. Check the radiator, hoses, and coolant levels regularly. Overheating can cause engine damage, so ensure the cooling system is functioning properly.

How to Change the Oil and Fuel Filter?

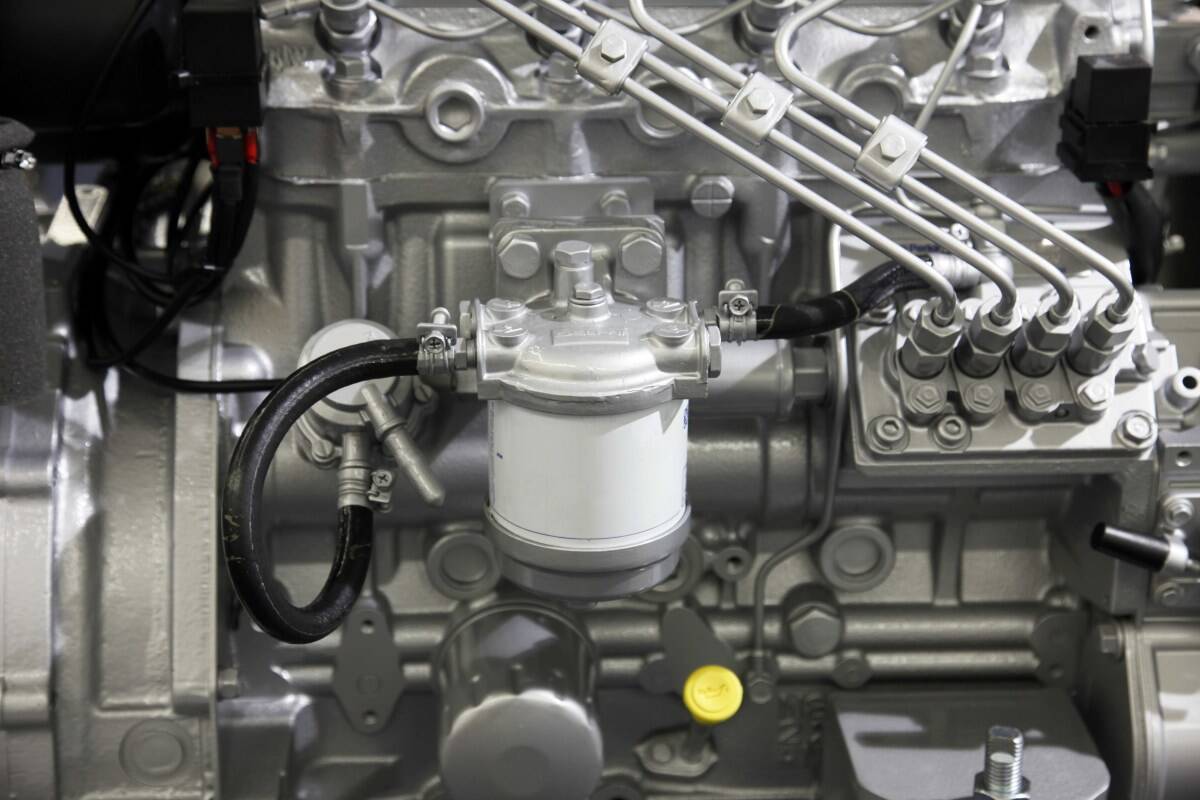

Changing the oil and fuel filter is a fundamental maintenance task. Regularly changing the oil helps maintain the engine's performance, while replacing the fuel filter ensures clean fuel delivery.

Changing oil and fuel filters regularly is one of the most critical maintenance tasks. Old oil and a clogged filter can damage the engine, reducing the generator's efficiency.

Changing the Oil

When changing the oil, make sure to use the right type and amount of oil specified by the manufacturer. Start the generator briefly to warm up the oil, then drain it completely. Afterward, replace the oil filter and fill in the new oil.

Replacing the Fuel Filter

The fuel filter prevents dirt and debris from entering the engine. Over time, it can get clogged, causing poor performance. To replace it, locate the filter and remove it by unscrewing the fittings. Install a new filter and tighten the fittings securely.

How to Clean and Maintain the Air Filter?

A clean air filter ensures that the engine gets the necessary airflow for combustion. It's vital to inspect and clean the air filter regularly to prevent dirt from affecting performance.

A clogged or dirty air filter reduces engine efficiency, leading to higher fuel consumption and possible engine damage. Regular cleaning can extend the life of your generator.

Air Filter Cleaning Process

Start by removing the air filter cover and inspecting the filter for dirt and debris. If it’s reusable, wash it with soap and water, and let it dry completely before reinstalling. If it’s disposable, replace it with a new one.

Importance of Proper Airflow

The generator requires proper airflow to prevent overheating and ensure efficient combustion. Ensure that the air intake and exhaust ports are clear from any obstructions, such as leaves or debris.

How to Test the Generator's Load Capacity?

Testing your generator’s load capacity is vital for understanding its performance under actual operating conditions. This step ensures that your generator can handle the required load without issues.

Load testing your generator helps determine whether it's capable of providing consistent power when needed. It’s an essential part of maintaining its performance over time.

Performing a Load Test

To perform a load test, connect a known load to the generator. Gradually increase the load while monitoring the generator’s voltage and frequency. If the generator can handle the load without fluctuating or stalling, it's in good shape.

Monitoring Performance During Load Testing

While testing, pay close attention to the temperature and vibration levels. Excessive heat or abnormal vibrations can indicate underlying issues that need to be addressed.

How to Clean and Maintain the Cooling System?

The cooling system is responsible for maintaining the engine's temperature and preventing overheating. Regular maintenance of this system is critical for ensuring reliable performance.

Cleaning the cooling system regularly helps prevent overheating and extends the life of your generator. Neglecting it could lead to major engine damage.

Inspecting the Radiator and Hoses

Check the radiator for dirt, dust, and any obstructions. Clean it thoroughly with water to ensure it’s not clogged. Also, inspect the hoses for any leaks or cracks. If you find any, replace them promptly.

Maintaining Coolant Levels

Check the coolant level frequently and top it up as necessary. Low coolant levels can cause the engine to overheat, leading to potential damage. Ensure you use the correct coolant type for your generator.

Conclusion

Regular generator maintenance is key to keeping your equipment in good working order. By following these steps, you can extend your generator’s lifespan and avoid costly repairs.

Buying And Technical Contact

You can contact us in many ways:

You can go to our website (URL: https://waltpower.com/contact/) and drop us a message.

You can email us:

Our Contact is: +8618717996108 (WhatsApp)