What I’ve actually seen go wrong - and how buyers misjudge the real cause

I’ve supplied diesel generator sets for years, and I’ll say this upfront:

When a brand-new diesel generator fails to keep running, it’s rarely because the generator itself is “bad.”

In most real projects I’ve handled, the shutdown happens because something around the generator - fuel, load, configuration, or commissioning - wasn’t properly aligned with how diesel engines actually behave.

Below, I’m not listing textbook causes. I’m sharing the real reasons I see most often, and where buyers usually misread the situation.

A new diesel generator that won’t keep running is usually reacting correctly to a problem, not causing it.

If you treat it as a mechanical failure instead of a system or setup issue, you’ll almost always fix the wrong thing first.

1. Air in the fuel system (by far the most common reason)

In practice, this is the number-one cause I see when a new generator starts, runs briefly, then stalls.

Why this happens

- New generators are typically shipped without fuel

- Fuel lines are empty after transport

- Manual priming is skipped or done improperly

Diesel engines cannot tolerate air in the fuel line. Even a small air pocket can cause:

- Rough running

- Unstable RPM

- Automatic shutdown within minutes

Where buyers go wrong

Many buyers assume:

“It started, so the fuel system must be fine.”

That assumption is wrong.

Starting does not mean the system is properly primed.

2. Load is too small (low-load protection or wet stacking)

This surprises many buyers, especially on first installation.

What I often see in Real Projects

- A 100 kVA generator installed

- Only 5–10 kVA of load connected

- Generator shuts down after warming up

Modern diesel generators are often configured with:

- Low-load protection

- Or conditions that quickly lead to wet stacking

Why this matters

Diesel engines are designed to work, not idle.

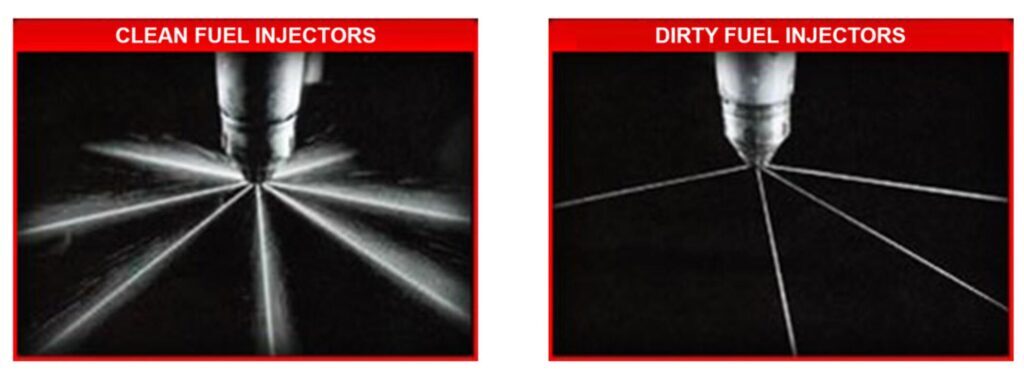

Running too lightly loaded causes:

- Incomplete combustion

- Carbon buildup

- Low exhaust temperature

- Protection-triggered shutdowns

My rule of thumb

If your generator consistently runs below 30% load, the sizing is wrong — not the generator.

3. The control system is doing exactly what it was designed to do

From the outside, this often looks like a “mysterious failure.”

From the controller’s point of view, it’s a normal protective response.

Common triggers I see

- Low oil pressure (often sensor-related)

- Abnormal coolant temperature readings

- Frequency or voltage outside limits

- Emergency stop circuit not fully closed

In many cases, the generator stops because the controller detects risk, not because the engine is failing.

Common mistake

Buyers focus entirely on the engine and ignore the alarm history in the controller, which usually explains the shutdown clearly.

4. Fuel quality problems during first fill

This happens more often than people expect, especially in temporary or developing-market installations.

Real cases I’ve encountered

- Diesel mixed with water from storage tanks

- Old diesel reused “just for testing”

- Contaminated jerry cans used for initial filling

A brand-new generator is often more sensitive than an older one.

Typical result

- Engine starts

- Runs briefly

- Fuel system protection triggers shutdown

Again, the generator is protecting itself - not failing.

5. ATS or wiring logic errors during installation

This is common when:

- The generator is new

- Commissioning was rushed

- ATS logic wasn’t tested under real conditions

Typical symptoms

- Generator starts normally

- Runs for 10–30 seconds

- Stops due to incorrect ATS signal interpretation

In these cases, the engine is fine.

The problem lies in control logic or wiring, not mechanical components.

6. Battery and charging system issues that get overlooked

“New” does not always mean “ready.”

I’ve seen new generators fail to keep running because:

- The battery wasn’t fully charged

- Charging alternator wiring wasn’t verified

- Battery capacity was marginal for the engine size

A weak battery can cause:

- ECU resets

- Controller faults

- Unexpected shutdowns shortly after startup

What I don’t usually blame first

Based on experience, these are rarely the root cause on new units:

- Engine manufacturing defects

- Alternator failure

- Generic assumptions like “bad-quality generator”

These issues exist, but far less often than installation, configuration, or commissioning mistakes.

When I actually start to worry

I only move toward deeper mechanical investigation when all of the following are confirmed:

- Fuel is clean and fully primed

- Load is correctly sized

- Controller alarms are verified and cleared

- ATS is isolated and tested

- Battery and charging system are confirmed healthy

If the generator still won’t run after that, then hardware inspection makes sense.

A conclusion buyers can actually use

If a new diesel generator won’t keep running, don’t ask “what’s broken?” first.

Ask instead:

- Is the fuel system fully primed and clean?

- Is the load appropriate for this generator size?

- What does the controller alarm history show?

- Has the system been properly commissioned under real operating conditions?

In my experience, answering these questions correctly resolves most “new generator failures” without replacing any major components.