Diesel fuel contamination destroys engines, clogs filters, and wastes money. Don’t let fuel negligence turn into an expensive disaster.

Diesel fuel maintenance means keeping fuel clean, dry, and stable to avoid engine failure, reduce downtime, and protect your investment.

When diesel fuel sits for months, it degrades. Water builds up. Microbes grow. Filters clog. Engines fail. That’s why fuel maintenance is not optional. It’s critical.

Why Is Diesel Fuel Maintenance Necessary?

Diesel fuel problems grow quietly until it’s too late. Poor fuel damages injectors, increases smoke, and leads to sudden failure.

Fuel maintenance prevents degradation, microbial growth, and water contamination that harm engine components and reduce generator lifespan.

When I visited a client last year, their backup generator failed during a routine test. The fuel was black, thick, and full of sludge. Water had settled at the bottom. They didn’t know diesel can go bad in just 6 months. Since then, I’ve seen dozens of similar cases. The root cause? Ignoring fuel.

Types of Diesel Fuel Contamination

| Contaminant | Source | Effects on System |

|---|---|---|

| Water | Condensation, leaks | Microbial growth, rust, filter plugging |

| Microbial Growth | Bacteria, fungi in water | Fuel sludge, corrosion, clogging |

| Particulates | Dirt, rust, degraded fuel | Injector damage, filter clogging |

| Oxidation | Long-term storage exposure | Gummy residue, poor combustion |

Proper diesel fuel maintenance stops these problems before they start.

What Are the Main Diesel Fuel Maintenance Methods?

Routine fuel cleaning prevents system failure and expensive repairs. Yet, many ignore this simple habit.

Main fuel maintenance methods include regular fuel polishing, tank cleaning, biocide treatments, and water separation systems.

Regular Fuel Polishing

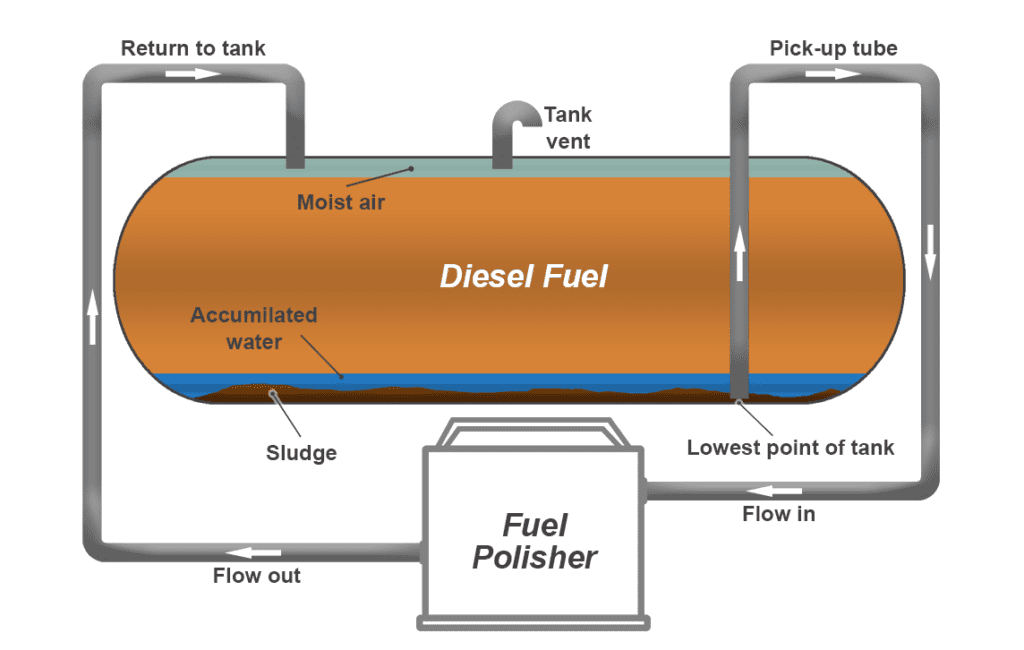

Fuel polishing removes water, sludge, and microbial contaminants. A fuel polishing system continuously filters and recirculates diesel to keep it clean.

Tank Cleaning

Manual tank cleaning removes solid contaminants and biofilm from tank surfaces. It’s necessary when sludge builds up or during major maintenance.

Water Separation

Water can enter diesel tanks through condensation or poor seals. Water separators and regular draining keep the fuel dry.

Biocide Treatment

Biocides kill microbial growth. I only use this when tests confirm bacteria or fungus in the fuel. Overuse can harm system seals and create resistance.

These practices work best in combination. I recommend a fuel maintenance schedule every 6 to 12 months.

How to Inspect and Test Diesel Fuel Quality?

Dirty fuel looks the same from the outside. Only testing shows what’s really inside. That’s how I catch problems early.

You can inspect diesel fuel visually for signs of contamination, and test it for water, microbial activity, and degradation using basic field kits.

Step-by-Step Visual Inspection

- Clarity Test: Good fuel is bright and clear. Cloudiness shows water or microbial contamination.

- Sediment Check: Let fuel settle in a glass jar. Sludge or dark particles are signs of contamination.

- Color Test: Fresh diesel is light yellow. A darker color means oxidation or age.

Field Testing Tools

| Test Type | Purpose | Tools Needed |

|---|---|---|

| Water Detection | Check for free and emulsified water | Water detection paste or kits |

| Microbial Test | Detect bacteria and fungus | Dip slides, ATP test kits |

| Fuel Stability | Test fuel degradation and oxidation | Portable stability kits |

I recommend testing every 3–6 months, especially before critical generator runs.

What Happens If You Don’t Maintain Diesel Fuel?

Ignoring fuel health is like ignoring oil changes. It shortens engine life, increases breakdowns, and costs more to fix.

Without maintenance, diesel fuel degrades, causing injector failures, black smoke, and emergency shutdowns that are expensive to repair.

I’ve seen a generator completely wrecked by algae growth in the tank. Filters clogged, injectors corroded, and the engine wouldn’t start during a power outage. The repair cost was triple the maintenance budget.

Consequences of Poor Diesel Fuel Maintenance

| Problem | Result |

|---|---|

| Fuel Sludge | Clogs filters and lines |

| Water Contamination | Corrodes injectors and tanks |

| Microbial Growth | Produces acids and biofilm |

| Fuel Oxidation | Reduces combustion quality and power output |

| Emergency Shutdown | Loss of power during critical operations |

Fuel-related breakdowns are preventable. It just takes awareness and routine care.

Conclusion

Clean fuel means reliable power. Never skip diesel fuel maintenance if uptime matters.

Buying And Technical Contact

You can contact us in many ways:

You can go to our website (URL: https://waltpower.com/contact/) and drop us a message.

You can email us:

Our Contact is: +8618717996108 (WhatsApp)