When a generator fails to start, most people blame the engine. But very often, it's the battery behind the problem.

The battery rating of a diesel generator is calculated based on voltage, capacity (Ah), and cold cranking amps (CCA), considering the generator's engine size, starting current, and ambient temperature.

If you're not sizing the battery correctly, you're risking failed starts, shorter battery life, and unwanted downtimes. Let’s break down how we get the right battery rating and why it matters.

What Parameters Influence Battery Sizing?

Many buyers underestimate how complex battery sizing is. They just look at voltage. But that’s only part of the story.

Battery sizing depends on engine displacement, starting system voltage, ambient temperature, and required starting duration. These factors help determine both battery capacity and cold cranking performance.

To begin with, every diesel generator requires a DC power source for cranking the engine. For most standard gensets, this is either a 12V or 24V battery system. But within that, the actual battery size can vary greatly depending on the engine’s starting requirements.

Key Factors That Affect Battery Rating

| Parameter | Description |

|---|---|

| Voltage (V) | 12V or 24V system depending on engine specs |

| Capacity (Ah) | How much energy the battery can store and supply |

| CCA (Cold Cranking Amps) | The battery’s ability to deliver high current at low temperatures |

| Engine Displacement | Larger engines need higher current to crank |

| Starting Time | Longer start durations require more stored energy |

| Ambient Temperature | Colder environments demand higher CCA |

When I work with OEM customers, we start by checking the engine manufacturer’s cranking current and starting duration recommendations. Then we factor in site conditions like minimum temperatures. Based on that, we choose a battery (or battery bank) that matches or exceeds those values.

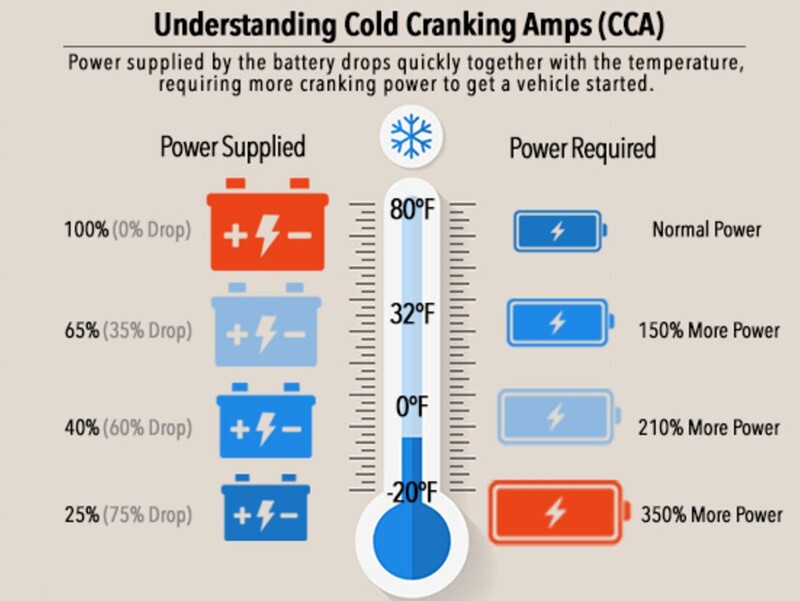

Why Is Cold Cranking Amps (CCA) So Important?

In cold weather, batteries work harder. That's when CCA becomes critical.

CCA measures the battery's ability to deliver a high burst of power in cold conditions. Higher CCA ratings ensure reliable starts even in low temperatures.

Imagine your diesel genset is installed in a remote area with freezing winters. If the battery doesn’t have enough CCA, it won’t crank the engine fast enough to start combustion. I’ve seen this issue too many times, especially with batteries sourced without checking CCA.

How to Choose the Right CCA Rating?

| Ambient Temperature | Recommended CCA |

|---|---|

| Above 10°C (50°F) | 80–100% of engine cranking current |

| 0°C to 10°C (32°F–50°F) | 100–125% |

| Below 0°C (32°F) | 125–150% or more |

Battery suppliers usually provide these ratings on the label. But remember: always match or exceed the engine manufacturer’s minimum CCA recommendation. If you're not sure, go higher—it's better to overestimate than face a failed start.

What Role Does Battery Capacity (Ah) Play?

A common mistake is choosing a battery just for its voltage and CCA, without checking capacity.

Battery capacity, measured in ampere-hours (Ah), determines how long the battery can supply current. A higher Ah rating supports longer cranking and backup for generator controllers.

Let’s say the genset fails to start in the first attempt. A higher capacity battery allows several attempts without voltage dropping too low. It also supports auxiliary circuits like the engine controller, sensors, and solenoids.

Recommended Capacity Based on Engine Size

| Engine Size | Suggested Battery Capacity (Ah) |

|---|---|

| <1L | 40–60 Ah |

| 1L–3L | 60–100 Ah |

| 3L–6L | 100–150 Ah |

| >6L | 150–200+ Ah |

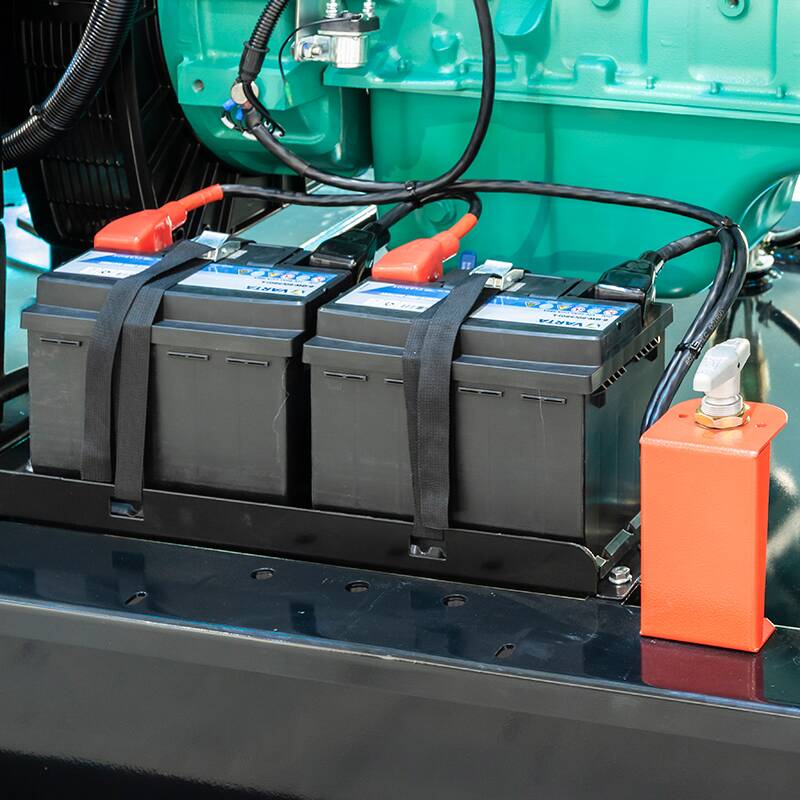

In some standby gensets, dual batteries are used in parallel to increase both capacity and reliability. This is especially true in mission-critical applications like hospitals or telecom sites. I usually recommend higher capacity batteries for regions with unstable power, where gensets must crank often.

How Do You Calculate the Battery Size for Your Generator?

Let’s put all the pieces together and walk through the process.

To calculate battery size, determine system voltage, cranking current, starting time, and minimum operating temperature. Then select a battery with matching or higher CCA and Ah rating.

Step-by-Step Battery Sizing

-

Identify Voltage Requirement

Most small generators use 12V. Larger ones (above 100kVA) use 24V systems. -

Get Engine Starting Current

Refer to the engine data sheet. Typical starting currents range from 200A to 800A. -

Estimate Starting Duration

Usually 5–10 seconds. Multiply this by the current to estimate total current draw. -

Check Minimum Temperature

If operating below 0°C, increase the required CCA by at least 25–50%. -

Select a Battery

Choose a battery or combination that meets:- Voltage = Engine system

- CCA ≥ Required cranking amps

- Ah ≥ Current x Duration (with margin)

Example Calculation

If an engine requires 500A for 10 seconds in 0°C:

- Voltage = 24V

- CCA needed = 500A × 1.25 = 625A

- Capacity = 500A × (10/3600) × 3 (safety factor) = ~5Ah

But to support auxiliary loads, a 100–150Ah battery is usually chosen.

In this case, a 24V system using two 12V, 120Ah, 650CCA batteries in series would work well.

Conclusion

Battery sizing is not just about voltage. Matching CCA and capacity to engine and site conditions ensures your diesel generator starts reliably, every time.

Buying And Technical Contact

You can contact us in many ways:

You can go to our website (URL: https://waltpower.com/contact/) and drop us a message.

You can email us:

Our Contact is: +8618717996108 (WhatsApp)