I’ve been involved in backup generator projects for years, and this question comes up more often than almost any other:

“How often should a backup generator actually be run?”

The technical answer is simple.

The real-world answer is not.

Most backup generators fail not because they are poorly made, but because they are rarely exercised correctly. In practice, I see this mistake repeated across factories, commercial buildings, telecom sites, and even well-funded projects.

This article explains what should happen — and why it often doesn’t.

The short answer (what most people are looking for)

A backup generator should be run at least once per month, under load, for 30–60 minutes.

If there’s only one sentence worth remembering, it’s this:

A standby generator that never runs is more likely to fail than one that runs regularly.

But this sentence alone doesn’t explain why so many owners still ignore it.

What “running a backup generator” really means

Most misunderstandings start here.

In real projects, I see three very different interpretations of “running the generator”:

- Starting it for 5–10 minutes with no load

- Letting it auto-start briefly during ATS self-tests

- Running it with real electrical load for a sustained period

Only the third one actually counts.

What doesn’t count (but people think it does)

These checks may look reassuring, but they don’t protect the generator:

- Starting the engine just to “see if it turns”

- Letting the engine idle with no load

- Monthly ATS tests that last only a few minutes

They confirm the battery and starter are alive — nothing more.

They do not prevent engine or system degradation.

Why monthly load runs matter (from field experience)

In real export projects, I’ve seen generators that were less than two years old fail during their first real blackout. Not because of design flaws — but because they had never been exercised properly.

Regular load operation prevents problems such as:

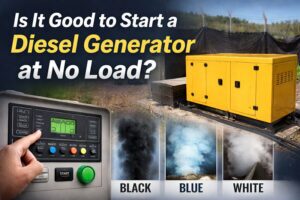

- Wet stacking in diesel engines

- Fuel system varnishing and injector fouling

- Moisture accumulation in alternator windings

- Turbocharger and exhaust carbon buildup

- False confidence in “standby-ready” equipment

Diesel engines are designed to work.

When they idle too often, they age badly.

How often is “often enough” - realistically?

Based on how backup generators are actually used, this is the framework I trust.

Recommended exercise schedule

- Frequency: Once per month

- Duration: 30–60 minutes

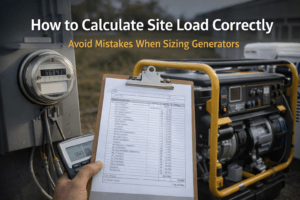

- Load level: Minimum 30–40% of rated load

- Method: Real site load or load bank (preferred if site load is unavailable)

For generators supporting critical infrastructure — data, telecom, medical, or process equipment — I usually recommend bi-weekly runs.

Why many people don’t run their backup generators

This is the part most technical articles avoid. It’s also where most failures originate.

1. “It’s backup — why wear it out?”

This is the most common logic error I hear.

Many owners believe running the generator reduces its lifespan. In reality, the opposite is usually true.

A diesel generator that runs regularly under proper load will almost always outlast one that sits idle for years.

2. No easy way to apply load

In many installations:

- The generator is electrically isolated

- Loads cannot be switched conveniently

- Shutting down equipment for testing is disruptive

So testing gets postponed — indefinitely.

This is exactly why load banks exist, yet they’re often removed from the budget.

3. “It passed commissioning, so we’re done”

Commissioning proves initial functionality, not long-term reliability.

I’ve seen generators pass FAT and SAT perfectly, then fail two years later due to fuel degradation or control issues — simply because they were never exercised again.

4. No one truly owns the responsibility

This happens more often than people admit:

- Procurement buys the generator

- Engineering installs it

- Operations assumes it’s automatic

- Maintenance focuses on visible equipment

The generator sits quietly in a corner — until the blackout arrives.

What I tell buyers who want real reliability

When someone asks me how to ensure their backup generator will actually work, my answer is usually this:

If you’re not willing to run it regularly, don’t assume it will save you during an outage.

It sounds blunt, but it’s honest.

A backup generator is not a fire extinguisher you forget on the wall.

It’s a mechanical system that needs movement, temperature, and load to stay reliable.

When monthly testing may not be enough

There are situations where I would not stop at monthly runs:

- High-humidity environments

- Cold climates with long idle periods

- Oversized generators operating at low load

- Sites storing diesel fuel for long durations

In these cases, testing frequency and fuel management matter as much as the generator itself.

Conclusion

Based on what I’ve seen across real projects:

Most backup generator failures are maintenance failures, not equipment failures.

Running the generator regularly isn’t about ticking a box.

It’s about ensuring the machine behaves the same way on day 500 as it did on day 1.