Turbocharging a generator is a concept that might sound unusual, but it’s worth exploring. What are the benefits and risks? And how would this affect the performance of the diesel engine?

Turbocharging a generator could increase engine power and efficiency. It involves forcing more air into the combustion chamber, which helps burn more fuel. This results in higher output and potentially better fuel economy. But it comes with challenges.

Turbocharging is primarily used to improve the power-to-weight ratio of an engine. By forcing more air into the combustion chamber, it can improve fuel efficiency and power output. But would it be practical or beneficial for diesel generators? Let’s dive in to explore.

What Is Turbocharging, and How Does It Work in Diesel Engines?

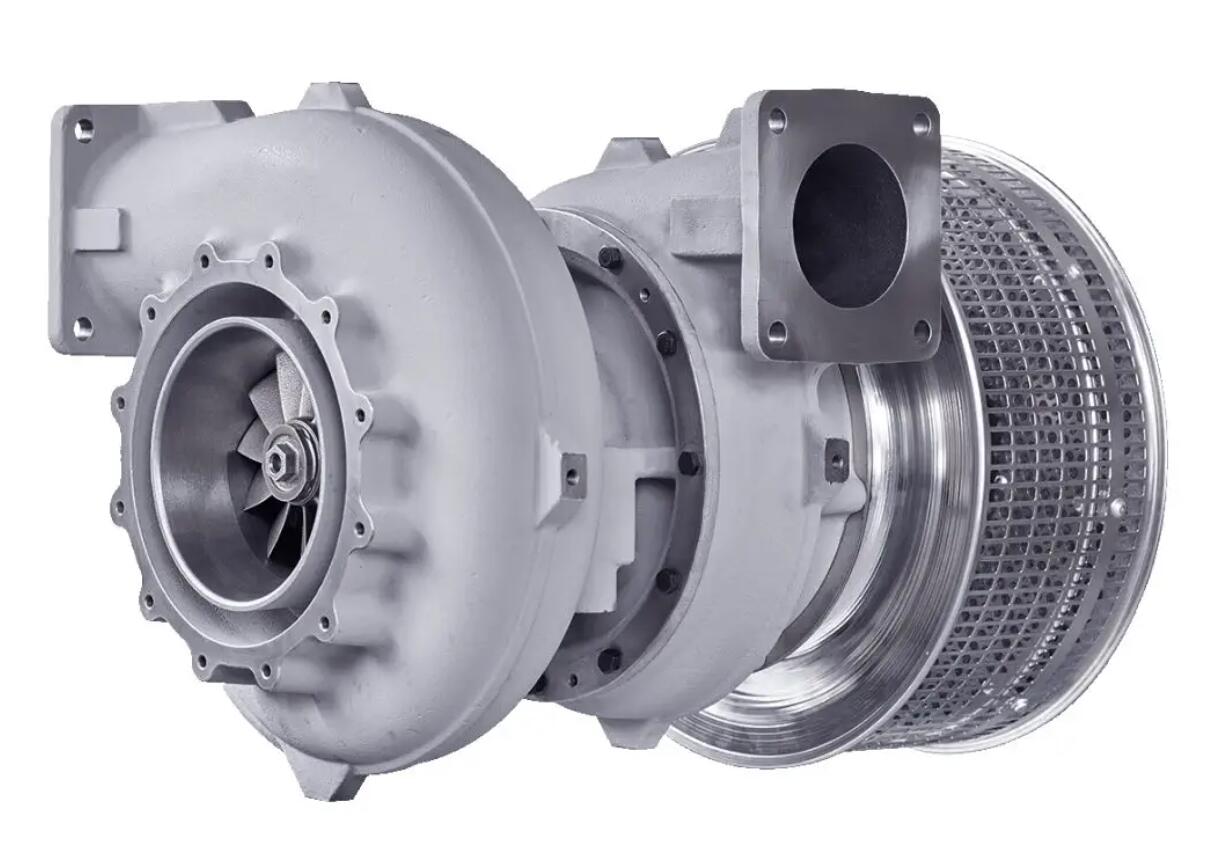

Turbocharging might seem like a complex idea, but it’s essentially a way of improving engine performance without significantly increasing engine size. A turbocharger is a turbine-driven forced induction device that compresses the air entering the engine.

Turbocharging works by using exhaust gases to spin a turbine that drives a compressor. This compressor forces more air into the engine, which allows more fuel to be burned, resulting in higher power output.

How a Turbocharger Boosts Diesel Engine Performance

In a diesel generator, the turbocharger serves to improve engine efficiency. The extra air that gets compressed into the combustion chamber results in better combustion of fuel. The more fuel burned efficiently, the more power the engine can produce.

But how does this apply specifically to generators? Diesel generators are designed to run for long periods, usually at a constant load. By turbocharging, you can get more power out of the same size engine. This may help the generator perform better in scenarios where high power output is needed continuously.

However, there are some risks involved. Let’s break it down:

Pros and Cons of Turbocharging a Diesel Generator

Pros

- Increased Power Output: The most immediate benefit is the ability to generate more power without increasing the engine's size. Turbochargers make generators more powerful by improving the air-fuel mixture.

- Better Fuel Efficiency: Since more air is forced into the combustion chamber, it helps achieve a more complete combustion of the fuel. This can lead to lower fuel consumption for the same amount of power.

- Improved High Altitude Performance: At higher altitudes, the air density decreases. Turbocharging helps by compressing the air and delivering more of it into the engine, allowing the generator to maintain performance even in challenging environments.

Cons

- Increased Complexity: Turbochargers add another layer of complexity to the generator’s engine. This could mean more maintenance and higher repair costs over time.

- Heat Generation: Turbochargers increase the amount of heat generated in the engine. This could strain cooling systems and lead to overheating if not managed correctly.

- Potential Overboosting: If the turbocharger is not calibrated properly, it could cause too much air to enter the engine, leading to an imbalance in the air-fuel mixture and potentially damaging the engine.

What Challenges Arise from Turbocharging a Generator?

Turbocharging is not a simple plug-and-play upgrade. There are several technical challenges and considerations that come into play when applying a turbocharger to a diesel generator.

One of the biggest challenges is ensuring that the turbocharger is sized correctly for the engine. Too small, and it won’t provide enough boost. Too large, and the engine could be overwhelmed.

Engine Overload and Reliability Issues

One of the challenges of turbocharging a diesel generator is the risk of overloading the engine. Diesel engines are designed to run at a certain efficiency and load range. By increasing the power output through a turbocharger, there’s a risk of pushing the engine beyond its reliable operating limits.

This could affect the engine’s lifespan and reliability, especially if the generator is used continuously under high loads. Moreover, the increased power output could require upgraded components like the cooling system, exhaust system, and fuel delivery system to handle the extra stress.

Cooling and Exhaust Management

A key component of turbocharging is heat management. The additional heat generated by the turbo can increase the chances of overheating. Proper cooling systems become even more critical in turbocharged generators to avoid thermal damage.

Maintenance and Service Life

Adding a turbocharger to a generator increases the mechanical complexity of the engine. It requires careful tuning and regular maintenance to ensure it continues to perform optimally. The bearings in the turbocharger, in particular, are highly sensitive to dirt, oil contamination, and wear. If not regularly checked and maintained, these could fail, leading to costly repairs.

Conclusion

Turbocharging a generator can result in increased power output, improved fuel efficiency, and enhanced performance at higher altitudes. However, this comes with the potential for overheating, more complex maintenance, and the risk of overloading the engine. Understanding these trade-offs is key when considering whether or not to turbocharge your diesel generator.

Buying And Technical Contact

You can contact us in many ways:

You can go to our website (URL: https://waltpower.com/contact/) and drop us a message.

You can email us:

Our Contact is: +8618717996108 (WhatsApp)